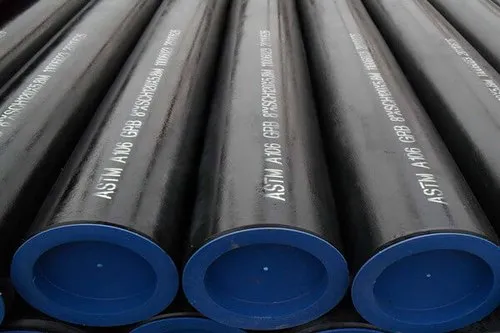

ASTM A106 Grade B Pipe

Talk To Us – We’re Here To Help

ASTM A106 Gr B Pipes, ASTM A106 Gr. B Carbon Steel Pipes, ASTM A106 Carbon Steel Gr. B Pipes, ASTM A106 Gr. B Seamless Pipes, Carbon Steel A106 Grade B Pipes Manufacturer in India.

ASTM A106 Grade B Seamless Pipes, Grade B A106 Carbon Steel Pipes Stockist, A106 Pipes, ASTM A106 Gr B Pipes Supplier, ASTM A106 Gr B Black Pipes, ASTM A106 Gr. B Seamless Pipe in Mumbai, India.

Solitaire Steel is a prominent supplier and exporter of ASTM A106 Grade B Pipes, valued for their seamless structure and excellent performance in high-temperature settings. These A106 Grade B Pipes are designed to meet rigorous industrial demands, with the flexibility to be bent, coiled, flanged, and welded as needed. Pipes under 2 inches are typically cold-drawn, while larger sizes (2 inches and above) are hot-finished for added strength and structural integrity, making them suitable for various fabrication processes.

With an extensive selection of steel products, including A106 Pipe Material, Solitaire Steel ensures each item meets high standards and certifications, including ASTM A106 GR. B. Every ASTM A106 Grade B Carbon Steel Pipe undergoes independent testing and quality checks, minimizing defects and guaranteeing reliable performance in exports.

ASTM A106 GR. B Carbon Steel Seamless Pipes are widely used in industries requiring high-temperature service, such as industrial plants, power generation facilities, refineries, and chemical processing plants. The ASTM A106 GR. B specification mandates that these pipes undergo solution annealing during heat treatment to optimize ferrite restoration.

Notably, ASTM A106 GR. B Carbon Steel Round Pipes require careful welding to prevent overheating, as excessive heat can slow the cooling rate, affecting weld integrity. Solitaire Steel offers a complete inventory of ASTM A106 Grade B Pipes, ready to support your project needs with high-quality, dependable products.

ASTM A106 Gr.B Specification

| Category | Details |

| Standards | ASTM, ASME, API, ANSI B 36.10 |

| Craft | Cold Rolled and Cold Drawn |

| ANSI Standard | B1.20. |

| Grades | ASTM A106 Grade A, Gra B, Gra C |

| Type | ERW, Welded, Fabricated, Seamless |

| Size | 1/2” NB to 36” NB |

| Length | Minimum 3 Meters, Maximum 18 Meters |

| Thickness | 3-12mm |

| Specialized in | Large Diameter ASTM A106 Grade B Pipe |

| Schedules | Schedule 20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

| ASME Standard | B36.10M |

| Tolerance | Cold Drawn Pipe: +/-0.1mm Cold Rolled Pipe: +/-0.05mm |

| End | Plain End, Beveled End, Threaded End |

ASTM A106 Pipe Chemical Composition

| Grade B | Grade A | Grade C | |

| Manganese % | 0.29 to 1.06 | 0.27 to 0.93 | 0.29 to 1.06 |

| Carbon max. % | 0.30 | 0.25 | 0.35 |

| Sulfur, max. % | 0.025 | 0.025 | 0.025 |

| Phosporous, max. % | 0.025 | 0.025 | 0.025 |

| Silicon, min. % | 0.10 | 0.10 | 0.10 |

A106 Seamless Pipe Mechanical Properties

| Seamless | Grade B | Grade A | Grade C |

| Yield Strength, min., psi | 35,000 | 30,000 | 40,000 |

| Tensile Strength, min., psi | 60,000 | 48,000 | 70,000 |

ASTM A106 Gr. B Equivalent

| Former | New | |||

| Execution | Standard | Material | Standard | Material |

| Seamless | ASTM A106 | GRADE B | EN 10216-2 | P265GH |

| Seamless | ASTM A333 | GRADE 6 | EN 10216-4 | P265NL |

| Welded | API 5L | Grade B | EN 10208-2 | L245NB |

| Welded | API 5L | Grade X52 | EN 10208-2 | L360NB |

| Seamless | API 5L | Grade B | EN 10208-2 | L245NB |

| Seamless | API 5L | Grade X52 | EN 10208-2 | L360NB |

ASTM A106 Grade B Pipe Dimensions

| Nominal Size (inches) | Outside Diameter (OD) (inches) | Wall Thickness (inches) | Schedule 40 Wall Thickness (inches) | Schedule 80 Wall Thickness (inches) |

|---|---|---|---|---|

| 1/8 | 0.405 | 0.049 | 0.068 | 0.095 |

| 1/4 | 0.540 | 0.065 | 0.088 | 0.119 |

| 3/8 | 0.675 | 0.091 | 0.091 | 0.126 |

| 1/2 | 0.840 | 0.109 | 0.147 | 0.187 |

| 3/4 | 1.050 | 0.113 | 0.154 | 0.218 |

| 1 | 1.315 | 0.133 | 0.179 | 0.250 |

| 1 1/4 | 1.660 | 0.140 | 0.191 | 0.250 |

| 1 1/2 | 1.900 | 0.145 | 0.200 | 0.281 |

| 2 | 2.375 | 0.154 | 0.218 | 0.344 |

| 2 1/2 | 2.875 | 0.203 | 0.276 | 0.375 |

| 3 | 3.500 | 0.216 | 0.300 | 0.438 |

| 4 | 4.500 | 0.237 | 0.337 | 0.531 |

| 6 | 6.625 | 0.280 | 0.432 | 0.562 |

| 8 | 8.625 | 0.322 | 0.500 | 0.718 |

| 10 | 10.750 | 0.365 | 0.500 | 0.843 |

| 12 | 12.750 | 0.375 | 0.500 | 0.937 |

| 14 | 14.000 | 0.375 | 0.500 | 0.937 |

| 16 | 16.000 | 0.375 | 0.500 | 0.937 |

ASTM A106 Grade B Pipe Pressure Rating

| Max. Pressure Allowable (psi) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | OD | Sch | ||||||||||||

| (in) | (in) | 40 | 20 | 60 | 30 | 10 | 100 | 140 | 160 | XS | STD | 80 | XXS | 120 |

| 1/2 | 0.084 | 6358 | 10908 | 8575 | 6358 | 8575 | 17150 | |||||||

| 1/4 | 0.054 | 7985 | 10798 | 7985 | 10798 | |||||||||

| 3/4 | 1.005 | 5273 | 10220 | 7187 | 5273 | 7187 | 14373 | |||||||

| 3/8 | 0.0675 | 6606 | 9147 | 6606 | 9147 | |||||||||

| 1 | 1.0315 | 4956 | 9316 | 6670 | 4956 | 6670 | 13340 | |||||||

| 1 1/2 | 1.09 | 3739 | 7247 | 5158 | 3739 | 5158 | 10316 | |||||||

| 2 | 2.0375 | 3177 | 7097 | 4498 | 3177 | 4498 | 8995 | |||||||

| 1 1/4 | 1.066 | 4133 | 7380 | 5638 | 4133 | 5638 | 11276 | |||||||

| 2 1/2 | 2.0875 | 3460 | 6391 | 4704 | 3460 | 4704 | 9408 | |||||||

| 3 1/2 | 4 | 2769 | 3896 | 2769 | 3896 | |||||||||

| 3 | 3.05 | 3024 | 6132 | 4200 | 3024 | 4200 | 8400 | |||||||

| 5 | 5.0563 | 2273 | 5505 | 3303 | 2273 | 3303 | 6606 | 4404 | ||||||

| 6 | 6.0625 | 2071 | 5318 | 3195 | 2071 | 3195 | 6390 | 4157 | ||||||

| 32 | 32 | 1054 | 766 | 957 | 478 | 574 | ||||||||

| 4 | 4.05 | 2581 | 5782 | 3670 | 2581 | 3670 | 7339 | 4769 | ||||||

| 8 | 8.0625 | 1829 | 1420 | 2307 | 1574 | 3375 | 4613 | 5147 | 2841 | 1829 | 2841 | 4971 | 4085 | |

| 12 | 12.075 | 1560 | 961 | 2160 | 1268 | 3244 | 4324 | 5042 | 1922 | 1441 | 2644 | 3843 | 3843 | |

| 10 | 10.075 | 1664 | 1140 | 2279 | 1399 | 3277 | 4558 | 5128 | 2279 | 1664 | 2708 | 4558 | 3847 | |

| 14 | 14 | 1533 | 1092 | 2079 | 1313 | 875 | 3283 | 4375 | 4921 | 1750 | 1313 | 2625 | 3829 | |

| 18 | 18 | 1530 | 849 | 2042 | 1192 | 681 | 3147 | 4252 | 4848 | 1361 | 1021 | 2553 | 3743 | |

| 16 | 16 | 1531 | 956 | 2009 | 1148 | 766 | 3157 | 4404 | 4882 | 1531 | 1148 | 2585 | 3733 | |

| 20 | 20 | 1455 | 919 | 1989 | 1225 | 613 | 3138 | 4288 | 4824 | 1225 | 919 | 2526 | 3675 | |

| 24 | 24 | 1405 | 766 | 1978 | 1147 | 510 | 3126 | 4210 | 4786 | 1021 | 766 | 2489 | 3700 | |

| 30 | 30 | 817 | 1021 | 510 | 817 | 613 | ||||||||

| 22 | 22 | 835 | 1949 | 1114 | 557 | 3063 | 4176 | 4733 | 1114 | 835 | 2506 | 3619 | ||

| 36 | 36 | 1021 | 681 | 851 | 425 | 510 | ||||||||

| 34 | 34 | 992 | 721 | 901 | 450 | 540 | ||||||||

| 42 | 42 | 875 | 583 | 729 | 438 | |||||||||

A106 Pipe Weight Chart

| Other Diameter | Size | WT | Weight | Inside Diameter of Pipe | Schedule Pipe # |

Gallon | XXHY Standard to | Modulus Section |

|---|---|---|---|---|---|---|---|---|

| 0.0147 | 1.009 | 0.0546 | 80 | .00122 | XHY | .00478 | ||

| 0.084 | 1/2 | 0.0109 | 0.085 | 0.0622 | 40 | .00158 | STD | .00407 |

| 0.0188 | 1.031 | 0.0464 | 160 | .00088 | .00528 | |||

| 0.0154 | 1.048 | 0.0742 | 80 | .00225 | XHY | .00853 | ||

| 1.005 | 3/4 | 0.0113 | 1.013 | 0.0824 | 40 | .00277 | STD | .00705 |

| 0.0219 | 1.095 | 0.0612 | 160 | .00153 | .01006 | |||

| 0.0179 | 2.017 | 0.0957 | 80 | .00374 | XHY | .01606 | ||

| 1.0315 | 1 | 0.0133 | 1.068 | 1.0049 | 40 | .00449 | STD | .01328 |

| 0.0250 | 2.085 | 0.0815 | 160 | .00271 | .01904 | |||

| 0.0191 | 3.000 | 1.0278 | 80 | .00666 | XHY | .02913 | ||

| 1.066 | 1 1/4 | 0.0140 | 2.027 | 1.0380 | 40 | .00777 | STD | .02346 |

| 0.0250 | 3.077 | 1.0160 | 160 | .00549 | .03421 | |||

| 0.0200 | 3.063 | 1.0500 | 80 | .00918 | XHY | .04118 | ||

| 1.090 | 1 1/2 | 0.0145 | 2.072 | 1.0610 | 40 | .01058 | STD | .03262 |

| 0.0281 | 4.086 | 1.0338 | 160 | .00730 | .05079 | |||

| 0.0154 | 3.066 | 2.0067 | 40 | .01743 | STD | .05606 | ||

| 2.0375 | 2 | 0.0109 | 2.064 | 2.0157 | 10 | .01898 | .04205 | |

| 0.0218 | 5.003 | 1.0939 | 80 | .01534 | XHY | .07309 | ||

| 0.0281 | 6.029 | 1.0813 | .01344 | .08666 | ||||

| 0.0250 | 5.068 | 1.0875 | .01434 | .08045 | ||||

| 0.0344 | 7.047 | 1.0687 | 160 | .01161 | .09806 | |||

| 0.0203 | 5.080 | 2.0469 | 40 | .02487 | STD.0 | 1.00640 | ||

| 0.0216 | 6.014 | 2.0443 | .02435 | 1.01169 | ||||

| 2.0875 | 2 1/2 | 0.0120 | 3.053 | 2.0635 | 10 | .02833 | .06870 | |

| 0.0250 | 7.002 | 2.0375 | .02301 | 1.02468 | ||||

| 0.0375 | 10.002 | 2.0125 | 160 | .01842 | 1.06371 | |||

| 0.0276 | 7.067 | 2.0323 | 80 | .02202 | XHY | 1.03386 | ||

| 3.050 | 3 | 0.0120 | 4.034 | 3.0260 | .04336 | 1.00411 | ||

| 0.0172 | 6.012 | 3.0156 | .04064 | 1.04265 | ||||

| 0.0156 | 5.058 | 3.0188 | .04147 | 1.03122 | ||||

| 0.0188 | 6.066 | 3.0124 | .03984 | 1.05342 | ||||

| 0.0250 | 8.069 | 3.0000 | .03672 | 1.09372 | ||||

| 0.0216 | 7.058 | 3.0068 | 40 | .03840 | STD.0 | 1.07241 | ||

| 0.0281 | 9.067 | 2.0938 | .03521 | 2.01207 | ||||

| 0.0438 | 14.034 | 2.0624 | 160 | .02811 | 2.08774 | |||

| 0.0300 | 10.026 | 2.0900 | 80 | .03431 | XHY | 2.02253 | ||

| 4.00 | 3 1/2 | 0.0120 | 4.098 | 3.0760 | 10 | .05768 | 1.03776 | |

| 0.0250 | 10.002 | 3.0500 | .04998 | 2.06001 | ||||

| 0.0281 | 11.017 | 3.0438 | .04821 | 2.08562 | ||||

| 0.0226 | 9.012 | 3.0548 | 140 | .05136 | STD.0 | 2.03939 | ||

| 0.0318 | 12.052 | 3.0364 | 80 | .04617 | XHY | 3.01400 | ||

| 0.0156 | 7.024 | 4.0188 | .07156 | 2.02354 | ||||

| 0.0188 | 8.067 | 4.0124 | .06942 | 2.06296 | ||||

| 1.0125 | 66.014 | 4.0375 | .07809 | 23.01237 | ||||

| 4.05 | 4 | 0.0120 | 5.062 | 4.0260 | 10 | .07404 | 1.07612 | |

| 0.0203 | 9.032 | 4.0094 | .06838 | 2.08173 | ||||

| 0.0237 | 10.080 | 4.0026 | 40 | .06613 | STD.0 | 3.02145 | ||

| 0.0250 | 11.036 | 4.0000 | .06528 | 3.03611 | ||||

| 0.0219 | 10.002 | 4.0062 | .06725 | 3.00184 | ||||

| 0.0281 | 12.067 | 3.0938 | 60 | .06326 | 3.07021 | |||

| 0.0337 | 15.000 | 3.0826 | 80 | .05972 | XHY | 4.02713 | ||

| 0.0312 | 13.097 | 3.0876 | .06126 | 4.00273 | ||||

| 0.0438 | 19.002 | 3.0624 | 120 | .05361 | 5.01790 | |||

| 5.0563 | 5 | 0.0188 | 10.080 | 5.0187 | 1.00979 | 4.01161 | ||

| 0.0531 | 22.053 | 3.0438 | 160 | .04822 | 5.08997 | |||

| 0.0219 | 12.051 | 5.0125 | 1.00716 | 4.07279 | ||||

| 0.0281 | 15.087 | 5.0001 | 1.00204 | 5.08644 | ||||

| 0.0312 | 17.051 | 4.0939 | .099647 | 6.04074 | ||||

| 0.0258 | 14.063 | 5.0047 | 40 | 1.00391 | STD.0 | 5.04500 | ||

| 0.0375 | 20.080 | 4.0813 | 80 | .09449 | XHY | 7.04300 | ||

| 0.0344 | 19.019 | 4.0875 | .09696 | 6.09358 | ||||

| 0.0500 | 27.006 | 4.0563 | 120 | .08495 | 9.02534 | |||

| 6.0625 | 6 | 0.0109 | 7.059 | 6.0407 | 5 | 1.06748 | 3.05769 | |

| 0.0134 | 9.030 | 6.0357 | 10 | 1.06488 | 4.03475 | |||

| 0.0625 | 32.099 | 4.0313 | 160 | .07590 | 10.07976 | |||

| 0.0156 | 10.079 | 6.0313 | 1.06260 | 5.00107 | ||||

| 0.0203 | 13.094 | 6.0219 | 1.05780 | 6.03804 | ||||

| 0.0219 | 15.000 | 6.0187 | 1.05620 | 6.08261 | ||||

| 0.0188 | 12.094 | 6.0249 | 1.05937 | 5.09351 | ||||

| 0.0250 | 17.004 | 6.0125 | 1.05306 | 7.06905 | ||||

| 0.0312 | 21.006 | 6.0001 | 1.04688 | 9.03416 | ||||

| 0.0344 | 23.010 | 5.0937 | 1.04391 | 10.0111 | ||||

| 0.0280 | 18.099 | 6.0065 | 40 | 1.05008 | STD.0 | 8.04958 | ||

| 0.0375 | 25.005 | 5.0875 | 1.04082 | 10.0893 | ||||

| 0.0500 | 32.074 | 5.0625 | 1.02909 | 13.0711 | ||||

| 0.0432 | 28.060 | 5.0761 | 80 | 1.03541 | XHY | 12.0224 | ||

| 0.0625 | 40.009 | 5.0375 | 1.01787 | 16.01821 | ||||

| 0.0562 | 36.043 | 5.0501 | 120 | 1.02346 | 14.09806 | |||

| 0.0864 | 53.021 | 4.0897 | .09784 | XXHY | 20.0025 | |||

| 0.0719 | 45.039 | 5.0187 | 160 | 1.00977 | 17.08243 | |||

| 1.0000 | 60.013 | 4.0625 | .08727 | 21.07719 |

Application of ASTM A106 Grade B Pipe

- Ship Building

- Fossil Fuel Power Plants

- Marine Applications

- Refineries

- Boilers

- Heat Exchangers

- Nuclear Power

- Paper & Pulp

- Condensers

- Power Plants

Supply and Exporter

FAQs

ASTM A106 Grade B is a mild steel pipe material widely used in industrial plants, refineries, and chemical plants. It requires solution annealing to restore ferrite in the steel.

ASTM A106 Grade B is equivalent to ASTM A53 Grade B, API 5L Grade B, DIN 17175 St35.8, JIS G3454 STPG 370, and BS 3601 360A. These standards have comparable chemical compositions and mechanical properties, making them suitable for high-temperature applications.

SA-106 Gr. B is a plain carbon steel commonly used for high-temperature applications. It forms a thick oxide layer when exposed to high heat.