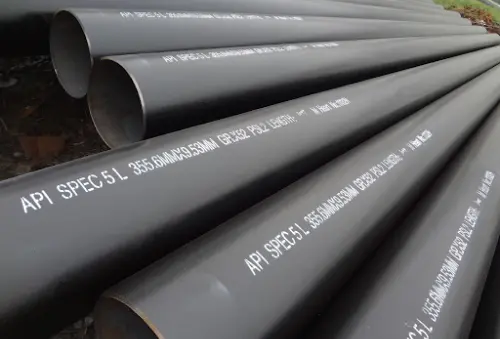

API 5L X52 Pipe

Talk To Us – We’re Here To Help

API 5L X52 PSL2 Pipe, L360 Welded Pipe Exporter, API 5L X52 ERW Pipe at Best Price in India.

Manufacturer of API 5L X52 ERW and Seamless Pipe, L360 PSL1 material and API 5L X52 Pipe Supplier.

Solitaire Steel is a prominent manufacturer, supplier, and exporter of API 5L Grade X52 pipes, known for their exceptional mechanical strength, with a minimum yield strength of approximately 360 MPa. These pipes surpass the properties of API 5L Grade B, X42, and X46 in terms of chemical composition and mechanical performance. Widely used across various industries, API 5L X52 Line Pipes are highly resistant to corrosion, making them ideal for sour service environments.

During the production of API 5L Grade X52 pipes, special emphasis is placed on ensuring toughness and conducting impact tests, particularly for applications involving sour services, high pressure, and elevated temperatures. To protect against sulfur stress corrosion, which is common in sour wells, the surface of API 5L X52 pipes is often coated with anti-corrosion treatments like varnish, black oil paint, or anti-corrosion oil, enhancing their durability.

Additionally, this grade is non-flammable, making it suitable for sensitive projects such as nuclear, thermal, geothermal, and hydro power generation. API 5L X52 Pipe is also used in various applications including flood control, textile industries and sugar industries, and construction projects. They are designed to convey gas, steam, and fluids efficiently. These pipes are available in two specification levels: PSL-1 and PSL-2, with PSL-1 pipes not requiring impact or non-destructive testing.

API 5L X52 Pipe Specification

X52 Pipe Sizes: Nominal Pipe Size 1/2″ to 48 ” O.D.

Wall Thickness: Schedule 10 through 160, STD, XS, XXS.

API 5L X52 Seamless Pipe: B (L245) – X42 (L290) – X52N (L360) – X60 (L415) – X65 (L450)

DIMENSION: FROM 1/4” UP TO 24”

API 5L X52 Welded Pipe: B (L245) – X42 (L290) – X52N (L360) – X60 (L415) – X65 (L450) – X70 (L485) – X80 (L555)

DIMENSION: FROM 1/2” UP TO 60”

Weld Alternatives: ERW, HF, DSAW/SAWL, SMLS, HSAW

X52 Pipe Product Specification Level: API 5L X52 PSL 2, API 5L X52 PSL 1

Additional Services: Internal Coating

API 5L Grade B Hot Selling Grades: API 5L X42 Pipe, API 5L X46 Pipe, API 5L X52 Pipe, API 5L X56 Pipe, API 5L X60 Pipe, API 5L X65 Pipe, API 5L X70 Pipe

API 5L X52 Pipe Composition Properties

| API 5L-PSL 1 Chemical Requirements | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade | Composition, % | |||||||

| C max | Mn max | P | S max | V max | Nb max | Ti max | ||

| min | max | |||||||

| B | 0.28 | 1.2 | – | 0.03 | 0.03 | c.d | c,d | d |

| X52 | 0.28 | 1.4 | – | 0.03 | 0.03 | d | d | d |

X70 Pipe Yield Strength

Grade |

Yield Strength |

Tensile Strength |

Yield to Tensile |

Elongation |

|---|---|---|---|---|

min. (KSI) |

min. (KSI) |

Ratio (max) |

% |

|

| API 5L X70 | 70 | 82 | 0.93 | 17 |

Chemical Element of API 5L Grade X52 Pipe

| Grade | C max | Mn max | P | S max | V max | Nb max | Ti max | |

|---|---|---|---|---|---|---|---|---|

| min | max | |||||||

| B | 0.28 | 1.2 | – | 0.03 | 0.03 | c.d | c,d | d |

| X52 | 0.28 | 1.4 | – | 0.03 | 0.03 | d | d | d |

API 5L X52 Pipe Equivalent Chart

| ASTM API 5L | Specification for line pipe | |

|---|---|---|

| Material Grade | PSL1 | L360 or x52 |

| Material Grade | PSL2 | L360N or X52N L360Q or X52Q L360M or X52M |

API 5L X52 pipe wall thickness & schedule chart

| NPS (in) |

Outside Diameter (in) |

API 5L X52 Pipe Schedule | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS | ||

| Wall Thickness (in) | ||||||||||||||

| 1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

| 1/4 | 0.540 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

| 3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

| 1/2 | 0.840 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | |||||||

| 3/4 | 1.050 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | |||||||

| 1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | 0.250 | 0.358 | |||||||

| 1 1/4 | 1.660 | 0.140 | 0.140 | 0.191 | 0.191 | 0.250 | 0.382 | |||||||

| 1 1/2 | 1.900 | 0.145 | 0.145 | 0.200 | 0.200 | 0.281 | 0.400 | |||||||

| 2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

| 2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

| 3 | 3.500 | 0.216 | 0.216 | 0.300 | 0.300 | 0.438 | 0.600 | |||||||

| 3 1/2 | 4.000 | 0.226 | 0.226 | 0.318 | 0.318 | |||||||||

| 4 | 4.500 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

| 5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | 0.500 | 0.625 | 0.750 | ||||||

| 6 | 6.625 | 0.280 | 0.280 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

| 8 | 8.625 | 0.250 | 0.277 | 0.322 | 0.322 | 0.406 | 0.500 | 0.500 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

| 10 | 10.750 | 0.250 | 0.307 | 0.365 | 0.365 | 0.500 | 0.500 | 0.594 | 0.719 | 0.844 | 1.000 | 1.125 | 1.000 | |

| 12 | 12.750 | 0.250 | 0.330 | 0.375 | 0.406 | 0.562 | 0.500 | 0.688 | 0.844 | 1.000 | 1.125 | 1.312 | 1.000 | |

| 14 | 14.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.500 | 0.750 | 0.938 | 1.094 | 1.250 | 1.406 | |

| 16 | 16.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.500 | 0.656 | 0.500 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18.000 | 0.250 | 0.312 | 0.438 | 0.375 | 0.562 | 0.750 | 0.500 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.594 | 0.812 | 0.500 | 1.031 | 1.281 | 1.500 | 1.750 | 1.969 | |

| 22 | 22.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.875 | 0.500 | 1.125 | 1.375 | 1.625 | 1.875 | 2.125 | ||

| 24 | 24.000 | 0.250 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.500 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

| 30 | 30.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.500 | ||||||||

| 32 | 32.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 34 | 34.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 36 | 36.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.750 | ||||||||

| 42 | 42.000 | 0.500 | 0.625 | 0.375 | 0.750 | |||||||||