Shell and Tube Heat Exchanger

Talk To Us – We’re Here To Help

Shell And Tube Heat Exchanger Manufacturer, Shell And Tube Heat Exchanger Diagram, Shell And Tube Heat Exchanger Manufacturers, ASME Code For Shell And Tube Heat Exchanger, Shell And Tube Heat Exchanger Supplier, Shell And Tube Heat Exchanger Manufacturers In India.

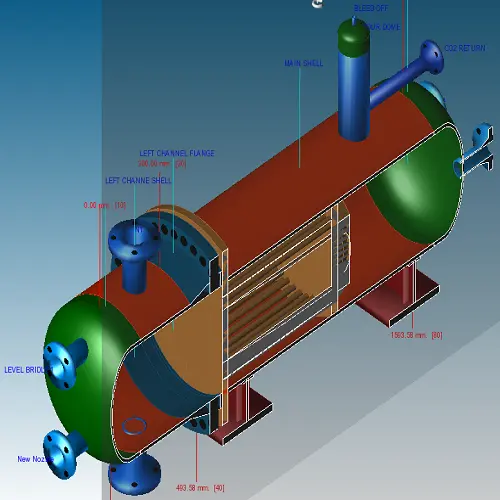

Solitaire Steel is a leading manufacturer, supplier, and exporter of top-notch shell and tube heat exchangers, widely used for heating and cooling fluids in various industrial and comfort applications. These heat exchangers feature a shell and a set of tubes. Fluids can be either liquids or gas, with one flowing through the tubes and the other circulating around the outside of the tubes within the shell. Our heat exchangers come in single-phase designs, suitable for straightforward heat transfer, and two-phase designs, ideal for processes that involve boiling or condensing fluids. Our shell and tube heat exchangers are designed for high thermal performance, whether using standard plain tubes or advanced enhanced surface tubes.

Shell and tube heat exchangers offer several key features

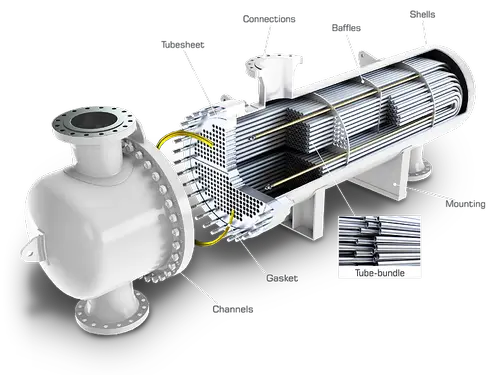

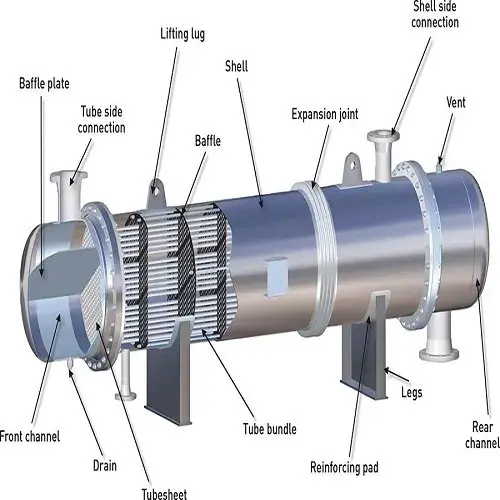

- Design: They have a cylindrical shell with a bundle of tubes running through it. Depending on the design, the tube bundle can be either U-shaped, known as a U-tube heat exchanger, or straight.

- Materials: These heat exchangers can be made from various materials like stainless steel or carbon steel, chosen based on the fluids and operating conditions.

- Tube Arrangement: Tubes can be arranged in different patterns such as parallel, triangular, or square. The arrangement influences heat transfer efficiency and pressure drop.

- Baffles: Inside the shell, baffles are used to guide the flow of the heat exchange fluid, which helps create turbulence and improves heat transfer efficiency.

- Tube Passes: This refers to how many times the fluid flows through the tube bundle. More passes can enhance heat transfer but might also increase the pressure drop.

Material of Construction Shell and Tube Heat Exchanger

Material of Construction | ||

| General Application | Special Application |

Shell | M.S (ERW Pipe) | S.S (Seamless Pipe) |

Tubes | Copper | CuNi 70:30 /CuNi 90:10 |

Tube-sheets | M.S | Ab-2, SS , Naval Brass |

End Covers | Cast Iron | LG-4, Gun Metal , SS |

Baffles & Tie Rods | M.S | S.S , Brass |

Shell and Tube Heat Exchanger Diagram

Model | Size | Capacity kcal/hr | Capacity kW | Oil Flow LPM |

FOC 2 | 4 ” X 18 “ | 1500 | 1.75 | 10-15 |

FOC 3 | 4 ” X 20 “ | 2400 | 2.8 | 15-30 |

FOC 5 | 4 ” X 24 “ | 3000 | 3.5 | 20-35 |

FOC 7.5 | 4 ” X 30 “ | 5000 | 6 | 30-55 |

FOC 10 | 6 ” X 18 “ | 6000 | 7 | 35-75 |

FOC 15 | 6 ” X 20 “ | 10500 | 12 | 60-100 |

FOC 20 | 6 ” X 24 “ | 13500 | 16 | 80-150 |

FOC 25 | 6 ” X 30 “ | 18000 | 21 | 100-190 |

FOC 30 | 8 ” X 24 “ | 24000 | 28 | 140-270 |

FOC 40 | 8 ” X 24 “ | 32000 | 37 | 180-370 |

FOC 50 | 8 ” X 30 “ | 34000 | 40 | 220-415 |

FOC 60 | 8 ” X 36 “ | 38000 | 44 | 240-465 |

FOC 70 | 8 ” X 42 “ | 45000 | 52 | 280-530 |

FOC 80 | 8 ” X 48 “ | 60000 | 70 | 320-600 |

FOC 100 | 10 ” X 54 “ | 75000 | 87 | 350-680 |

Shell and Tube Heat Exchanger Types

Shell and tube heat exchangers come in several types, each suited to different applications:

This design allows the tube bundle to expand and contract independently from the shell. It is ideal for applications where there are significant temperature changes, as it helps prevent thermal stresses. The tubes are fixed at one end while the other end is free to move.

In this design, the tube bundle is rigidly fixed to the tube sheets at both ends. This type is used when thermal expansion is minimal and there are fewer temperature fluctuations. It is generally simpler and more cost-effective but may be less adaptable to thermal expansion.

Applications of Shell and Tube Heat Exchanger

- Hydraulic Oil Cooling

- Lube Oil Cooling

- Pulp and Paper Industries

- Food Processing and Chemical Industries

- Pharmaceutical companies

- Quench Oil Cooling